What Are Waffle Slab Moulds?

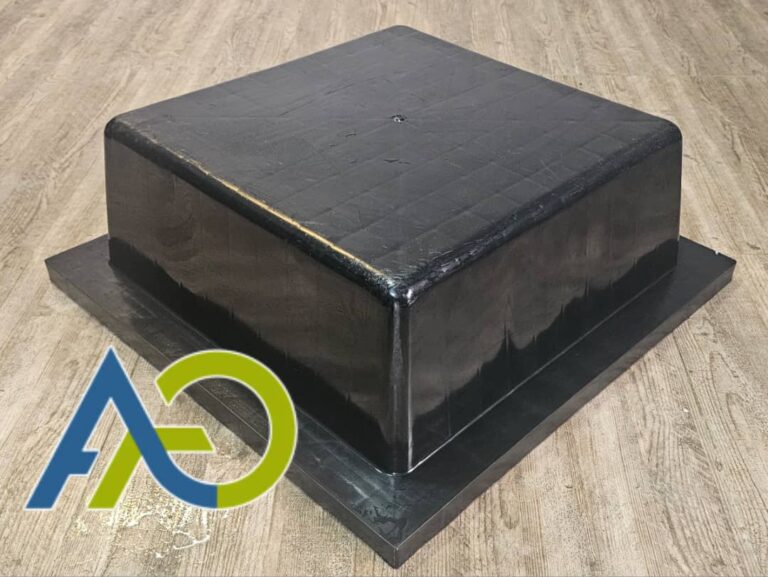

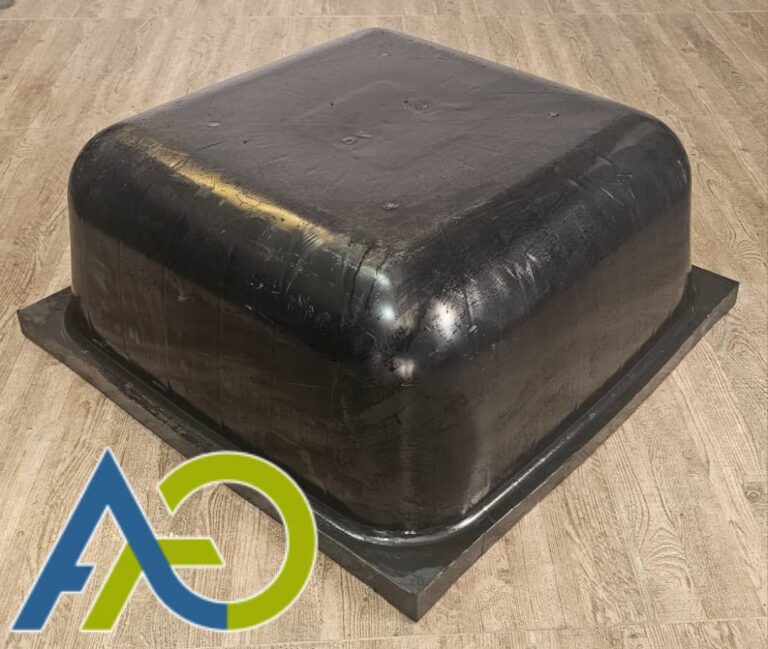

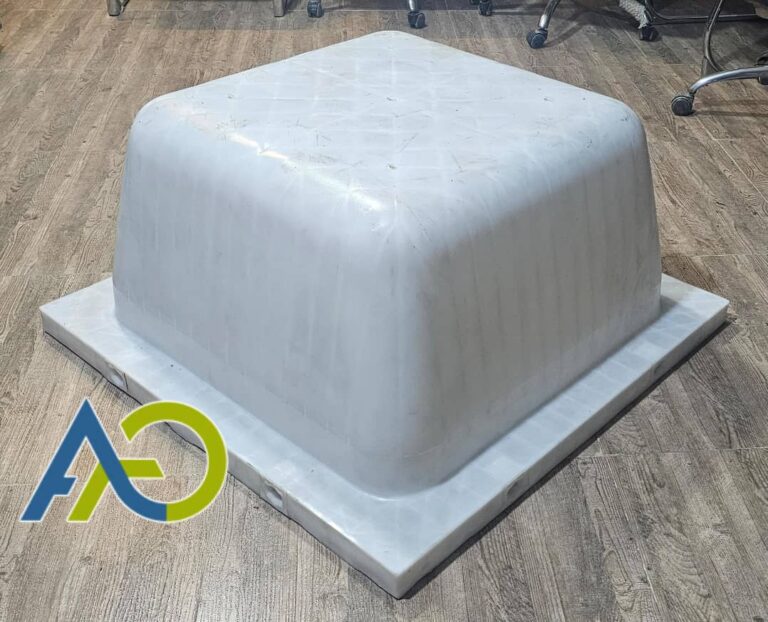

Waffle Slab Moulds are non-permanent moulds typically made from compressed plastic (polypropylene) or metal. They are used in the construction of waffle slabs, creating a grid-like pattern of voids in the concrete slab that significantly reduces the structure’s weight. Unlike traditional moulds that remain embedded in the structure after concrete curing, Waffle Slab Moulds are removed post-curing and can be reused multiple times. This reusability contributes to cost savings and environmental sustainability.Types of Waffle Slab Moulds

- One-Way Waffle Slab Moulds: These are used in projects where the load is primarily distributed in one direction. They are ideal for shorter spans.

- Two-Way Waffle Slab Moulds: Suitable for longer spans and loads distributed in two directions, these are commonly used in larger projects like halls and parking structures.

Applications of Waffle Slab Moulds in Construction

Due to their unique properties, Waffle Slab Moulds are utilized in various construction projects. Key applications include:- Residential and Commercial Buildings: Waffle slabs reduce structural weight and allow for larger spans without columns, making them popular in apartments and commercial complexes.

- Industrial Projects: Factories and warehouses requiring open, column-free spaces benefit from waffle slabs.

- Parking Structures and Large Halls: The aesthetic appeal and cost efficiency make this system ideal for multi-story parking and convention halls.

- Special Civil Projects: Certain bridges and unique structures in Iran have utilized waffle slabs for their benefits.

Advantages of Using Waffle Slab Moulds

Compared to other slab systems like bubble deck or traditional slabs, Waffle Slab Moulds offer several advantages:- Reduced Structural Weight: The voids created by the moulds reduce slab weight by up to 30 percent, lowering dead loads and enhancing earthquake resistance.

- Cost Savings: Lower concrete and rebar usage, combined with mould reusability, reduces project costs.

- High Execution Speed: Installing and removing moulds is quick and straightforward, shortening project timelines.

- Aesthetic Appeal: Waffle slabs provide a visually appealing grid pattern, ideal for exposed ceilings in spaces like parking garages.

- Environmental Sustainability: Reusable moulds and reduced material consumption make this system eco-friendly.

- Design Flexibility: The ability to create large spans without additional columns offers architects greater design freedom.

Disadvantages of Waffle Slab Moulds

Despite their numerous benefits, Waffle Slab Moulds have some limitations:- High Initial Cost: Purchasing high-quality moulds can involve significant upfront costs, though these are offset over time.

- Need for Skilled Labor: Executing waffle slabs requires trained teams, which may not be readily available in all regions.

- Limitations in Specific Projects: In structures with unique load patterns or irregular shapes, using Waffle Slab Moulds can be challenging.

Comparing Waffle Slabs with Other Slab Systems

Choosing the right slab system requires comparing Waffle Slab Moulds with alternatives:- Waffle Slab vs. Bubble Deck:

- Weight: Waffle slabs are generally lighter.

- Cost: Waffle moulds are more cost-effective in the long term due to reusability.

- Execution: Bubble deck requires more precision in mould placement.

- Waffle Slab vs. Beam and Block:

- Weight: Waffle slabs are lighter.

- Cost: Beam and block is cheaper initially, but waffle slabs are more economical for larger projects.

- Aesthetics: Waffle slabs offer a modern appearance.

- Waffle Slab vs. Cobiax:

- Weight: Both are lightweight, but waffle slabs offer more design flexibility.

- Cost: Waffle slabs have an edge due to mould reusability.

Key Considerations for Purchasing or Renting Waffle Slab Moulds

If you plan to buy or rent Waffle Slab Moulds, consider the following:- Mould Material: Plastic moulds are lighter and cheaper, while metal moulds offer greater durability.

- Mould Dimensions: Choose sizes based on the project type (one-way or two-way). Common sizes are 60 by 60 and 80 by 80 centimeters.

- Build Quality: High-quality moulds must withstand concrete pressure and environmental conditions.

- Price: Prices vary by material, size, and market. In 2025, plastic moulds typically cost between $6 and $30 per mould.

- Rent or Buy?: Renting is more economical for short-term projects, while purchasing is recommended for large or multiple projects.

- Reputable Supplier: Source from trusted suppliers to ensure quality and after-sales support.

How to Execute a Waffle Slab with Moulds

The execution of a waffle slab involves the following steps:- Design and Planning: Prepare detailed structural drawings considering load distribution and spans.

- Scaffolding and Formwork: Install scaffolding and support systems to bear the concrete weight.

- Mould Placement: Position Waffle Slab Moulds accurately and level them using appropriate tools.

- Reinforcement: Place rebar between and over the moulds as per the design.

- Concrete Pouring: Pour concrete evenly over the moulds.

- Mould Removal: After curing (typically 7 to 14 days), remove the moulds for reuse in future projects.

Notable Projects Using Waffle Slabs in Iran

Some prominent projects in Iran that have utilized waffle slabs include:- Large Cultural Buildings: Employed for weight reduction and aesthetic enhancement.

- Prestigious Universities: New buildings constructed with this system.

- Multi-Story Parking in Major Cities: Due to large spans and cost efficiency.

Frequently Asked Questions About Waffle Slab Moulds

- How many times can Waffle Slab Moulds be reused? High-quality moulds can be reused up to 50 times or more with proper maintenance.

- Are waffle slabs earthquake-resistant? Yes, their lighter weight and uniform load distribution enhance earthquake resistance.

- What is the cost of renting Waffle Slab Moulds? In Iran, rental costs typically range from $1 to $3 per mould per month, depending on size and quantity.

- What is the difference between one-way and two-way Waffle Slab Moulds? One-way moulds are for single-direction loading, while two-way moulds support loading in both directions.

Conclusion: Are Waffle Slab Moulds Suitable for Your Project?

Waffle Slab Moulds offer a modern and efficient solution for constructing concrete slabs, providing benefits like reduced weight, cost savings, and design flexibility. However, selecting this system requires careful consideration of project requirements, budget, and access to skilled labor. If you aim to enhance the efficiency of your construction projects, contact reputable suppliers for expert advice on purchasing or renting Waffle Slab Moulds.Waffle Slab Mould 60×60×18 cm

This mould, with dimensions of 60×60 cm and a height of 18 cm, is suitable for spans up to 7 meters in small residential and commercial projects. To calculate the number of moulds, 70% of the net ceiling area (excluding stairs, elevators, and columns) is considered. For a 500 m² ceiling, 350 m² of moulds are needed, which, divided by 0.36 m² (mould area), results in approximately 970 moulds. Concrete consumption is about 0.12-0.14 m³ per m² (slab thickness of 25 cm), which is 30% less than solid slabs. Buyers should consider the polypropylene quality (resistance to concrete pressure), polished surface (for easy demoulding without oil), and locking connections for secure assembly. The price of two-way waffle slab moulds in 2025 is approximately $4-$9 per mould. Used waffle slab moulds should be inspected for cracks and wear. Scaffolding with modular scaffolding and prop jacks is essential for 7-meter spans. The maximum span of 7 meters ensures safe deflection and vibration control. Precise mould arrangement per engineering plans optimizes material use. Purchasing from reputable suppliers like Alborz Ghaleb ensures quality and durability. Using standard mould release oil extends mould life up to 50 cycles. Consulting engineers for accurate load calculations and design is recommended.

Waffle Slab Mould 60×60×25 cm

This mould, with a height of 25 cm and dimensions of 60×60 cm, is suitable for spans up to 8 meters in commercial projects, multi-story parking lots, and small halls. For a 1000 m² ceiling, 700 m² of moulds are needed, which, divided by 0.36 m², results in approximately 1945 moulds. Concrete consumption is about 0.14-0.16 m³ per m² (slab thickness of 30 cm), which is more economical than traditional slabs. Buyers should ensure mould resistance to impact, lightweight design for easy handling, and a polished surface for exposed finishes. The price of two-way waffle slab moulds is approximately $4.4-$9.3 per mould. Used waffle slab moulds should have intact connections and no cracks. Scaffolding with modular scaffolding and prop jacks is safe for 8-meter spans. The maximum span of 8 meters ensures proper vibration and deflection control. Precise mould arrangement per engineering plans reduces material waste. Purchasing from Alborz Ghaleb guarantees after-sales service and quality. Proper maintenance with mould oil extends durability up to 50 cycles. Consulting structural engineers for project-specific load compatibility is essential.

Waffle Slab Mould 60×60×28 cm

This mould, with a height of 28 cm, is suitable for spans up to 8.5 meters in commercial projects and convention halls. For a 1000 m² ceiling, 700 m² of moulds are needed, resulting in approximately 1945 moulds. Concrete consumption is about 0.15-0.17 m³ per m² (slab thickness of 33 cm), which is 25% less than solid slabs. Buyers should check mould strength against concrete pressure, polished surface, and locking connections for easy installation. The price of two-way waffle slab moulds is approximately $5-$10 per mould. Used waffle slab moulds should be inspected for cracks and connection quality. Scaffolding with modular scaffolding and prop jacks is essential for 8.5-meter spans. The maximum span of 8.5 meters ensures safety and deflection control. Precise mould arrangement per engineering plans optimizes concrete and rebar costs. Purchasing from Alborz Ghaleb ensures product quality. Using standard mould release oil facilitates demoulding and extends mould life. Precise engineering design for this size improves seismic performance.

Waffle Slab Mould 60×60×30 cm

This mould, with a height of 30 cm, is suitable for spans up to 9 meters in commercial projects and parking lots. For a 1000 m² ceiling, approximately 1945 moulds are needed. Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm). Buyers should focus on polypropylene quality, lightweight design, and secure connections. The price of two-way waffle slab moulds is approximately $5.3-$11 per mould. Used waffle slab moulds should be checked for wear and cracks. Scaffolding with modular scaffolding and prop jacks is essential for 9-meter spans. The maximum span of 9 meters ensures safe vibration control. Precise arrangement per engineering plans reduces material use. Purchasing from Alborz Ghaleb guarantees quality. Maintenance with mould oil increases durability.

Waffle Slab Mould 75×75×18 cm

This mould, with dimensions of 75×75 cm and a height of 18 cm, is suitable for spans up to 8 meters in small commercial projects. For a 500 m² ceiling, 350 m² of moulds are needed, resulting in approximately 620 moulds (divided by 0.5625 m²). Concrete consumption is about 0.12-0.14 m³ per m² (slab thickness of 25 cm). Buyers should ensure mould strength, polished surface, and locking connections. The price of two-way waffle slab moulds is approximately $5.7-$14.3 per mould. Used waffle slab moulds should be free of cracks. Scaffolding with modular scaffolding and prop jacks is essential for 8-meter spans. The maximum span of 8 meters ensures safety. Precise mould arrangement reduces costs. Purchasing from Alborz Ghaleb ensures product quality.

Waffle Slab Mould 75×75×24 cm

This mould, with a height of 24 cm, is suitable for spans up to 9 meters in commercial projects and parking lots. For a 1000 m² ceiling, approximately 1245 moulds are needed (divided by 0.5625 m²). Concrete consumption is about 0.14-0.16 m³ per m² (slab thickness of 30 cm). Buyers should check mould strength, lightweight design, and polished surface. The price of two-way waffle slab moulds is approximately $6.2-$14.7 per mould. Used waffle slab moulds should be inspected for connections. Scaffolding with modular scaffolding and prop jacks is safe for 9-meter spans. The maximum span of 9 meters ensures deflection control. Purchasing from Alborz Ghaleb is recommended.

Waffle Slab Mould 75×75×28 cm

This mould, with a height of 30 cm, is suitable for spans up to 10 meters in commercial projects and halls. For a 1000 m² ceiling, approximately 1245 moulds are needed. Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm). Buyers should focus on material quality and locking connections. The price of two-way waffle slab moulds is approximately $6.7-$15 per mould. Used waffle slab moulds should be intact. Scaffolding with modular scaffolding and prop jacks is essential for 10-meter spans. The maximum span of 10 meters ensures safety. Purchasing from Alborz Ghaleb guarantees quality.

Waffle Slab Mould 75×75×30 cm

This mould, with a height of 30 cm, is suitable for spans up to 10 meters in commercial projects and halls. For a 1000 m² ceiling, approximately 1245 moulds are needed. Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm). Buyers should focus on material quality and locking connections. The price of two-way waffle slab moulds is approximately $7-$15.3 per mould. Used waffle slab moulds should be intact. Scaffolding with modular scaffolding and prop jacks is essential for 10-meter spans. The maximum span of 10 meters ensures safety. Purchasing from Alborz Ghaleb guarantees quality.

Waffle Slab Mould 80×80×25 cm

This mould, with dimensions of 80×80 cm and a height of 25 cm, is suitable for spans up to 10 meters in multi-story parking lots and convention halls. For a 1000 m² ceiling, approximately 1095 moulds are needed (divided by 0.64 m²). Concrete consumption is about 0.14-0.16 m³ per m² (slab thickness of 30 cm). Buyers should ensure mould resistance to concrete pressure, polished surface for aesthetic finishes, and secure connections. The price of two-way waffle slab moulds is approximately $7.3-$15.6 per mould. Used waffle slab moulds should be checked for cracks and wear. Scaffolding with modular scaffolding and prop jacks is essential for 10-meter spans. The maximum span of 10 meters ensures vibration and deflection control. Precise mould arrangement optimizes material use. Purchasing from Alborz Ghaleb ensures quality and after-sales service. Standard mould release oil ensures easy demoulding and extended durability.

Waffle Slab Mould 80×80×28 cm

This mould, with a height of 28 cm, is suitable for spans up to 11 meters in commercial and industrial projects. For a 1000 m² ceiling, approximately 1095 moulds are needed. Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 33 cm). Buyers should check mould strength, lightweight design, and polished surface for exposed finishes. The price of two-way waffle slab moulds is approximately $7.7-$16 per mould. Used waffle slab moulds should be inspected for connections and cracks. Scaffolding with modular scaffolding and prop jacks is essential for 11-meter spans. The maximum span of 11 meters ensures safety. Precise arrangement reduces costs. Purchasing from Alborz Ghaleb guarantees quality. Maintenance with mould oil increases durability.

Waffle Slab Mould 80×80×30 cm

This mould, with a height of 30 cm, is suitable for spans up to 11.5 meters in industrial projects and parking lots. For a 1000 m² ceiling, approximately 1095 moulds are needed. Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm). Buyers should focus on material quality, locking connections, and polished surface. The price of two-way waffle slab moulds is approximately $8-$16.3 per mould. Used waffle slab moulds should be intact. Scaffolding with modular scaffolding and prop jacks is essential for 11.5-meter spans. The maximum span of 11.5 meters ensures safety. Purchasing from Alborz Ghaleb is recommended.

Waffle Slab Mould 80×80×40 cm

This mould, with a height of 40 cm, is suitable for spans up to 12 meters in industrial projects and warehouses. For a 1000 m² ceiling, approximately 1095 moulds are needed. Concrete consumption is about 0.20-0.22 m³ per m² (slab thickness of 45 cm). Buyers should ensure mould strength, lightweight design, and secure connections. The price of two-way waffle slab moulds is approximately $8.8-$17 per mould. Used waffle slab moulds should be checked for cracks. Scaffolding with modular scaffolding and prop jacks is essential for 12-meter spans. The maximum span of 12 meters ensures safety. Purchasing from Alborz Ghaleb guarantees quality.

Waffle Slab Mould 83×83×40 cm

This mould, with dimensions of 83×83 cm and a height of 40 cm, is suitable for spans up to 12.5 meters in industrial projects and bridges. For a 1000 m² ceiling, approximately 1030 moulds are needed (divided by 0.6889 m²). Concrete consumption is about 0.20-0.22 m³ per m² (slab thickness of 45 cm). Buyers should ensure mould strength, polished surface, and locking connections. The price of two-way waffle slab moulds is approximately $9-$17.2 per mould. Used waffle slab moulds should be inspected for wear and cracks. Scaffolding with modular scaffolding and prop jacks is essential for 12.5-meter spans. The maximum span of 12.5 meters ensures deflection and vibration control. Precise mould arrangement optimizes material use. Purchasing from Alborz Ghaleb ensures quality and after-sales service. Standard mould release oil ensures easy demoulding and extended durability.

Waffle Slab Mould 85×85×30 cm

This mould, with dimensions of 85×85 cm and a height of 30 cm, is suitable for spans up to 13 meters in industrial projects and large parking lots. For a 1000 m² ceiling, approximately 970 moulds are needed (divided by 0.7225 m²). Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm). Buyers should focus on polypropylene quality, lightweight design for easy handling, and locking connections for secure assembly. The price of two-way waffle slab moulds is approximately $9.2-$17.5 per mould. Used waffle slab moulds should be inspected for cracks and connections. Scaffolding with modular scaffolding and prop jacks is essential for 13-meter spans. The maximum span of 13 meters ensures safety and vibration control. Precise mould arrangement reduces costs. Purchasing from Alborz Ghaleb guarantees quality. Maintenance with mould oil extends durability up to 50 cycles.

Waffle Slab Mould 90×90×30 cm

This mould, with dimensions of 90×90 cm and a height of 30 cm, is suitable for spans up to 14 meters in industrial projects, warehouses, and bridges. For a 1000 m² ceiling, approximately 865 moulds are needed (divided by 0.81 m²). Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm). Buyers should ensure mould resistance to concrete pressure, polished surface for aesthetic finishes, and secure connections. The price of two-way waffle slab moulds is approximately $9.4-$18.2 per mould. Used waffle slab moulds should be free of cracks. Scaffolding with modular scaffolding and prop jacks is essential for 14-meter spans. The maximum span of 14 meters ensures safety. Precise arrangement reduces material use. Purchasing from Alborz Ghaleb guarantees quality. Mould oil maintenance extends durability.Waffle Slab Mould 90×90×33 cm

This mould, with a height of 33 cm, is suitable for spans up to 14.5 meters in industrial and infrastructure projects. For a 1000 m² ceiling, approximately 865 moulds are needed. Concrete consumption is about 0.18-0.20 m³ per m² (slab thickness of 40 cm). Buyers should check mould strength, lightweight design, and locking connections. The price of two-way waffle slab moulds is approximately $9.8-$19 per mould. Used waffle slab moulds should be inspected for cracks and wear. Scaffolding with modular scaffolding and prop jacks is essential for 14.5-meter spans. The maximum span of 14.5 meters ensures safety. Precise arrangement reduces costs. Purchasing from Alborz Ghaleb guarantees quality. Maintenance with mould oil increases durability.Waffle Slab Mould 90×90×40 cm

This mould, with a height of 40 cm, is suitable for spans up to 15 meters in industrial projects, warehouses, and bridges. For a 1000 m² ceiling, approximately 865 moulds are needed. Concrete consumption is about 0.20-0.22 m³ per m² (slab thickness of 45 cm). Buyers should focus on polypropylene quality, polished surface, and locking connections. The price of two-way waffle slab moulds is approximately $10.3-$19.8 per mould. Used waffle slab moulds should be free of cracks. Scaffolding with modular scaffolding and prop jacks is essential for 15-meter spans. The maximum span of 15 meters ensures deflection control. Precise arrangement reduces material use. Purchasing from Alborz Ghaleb guarantees quality. Mould oil maintenance extends durability up to 50 cycles.Skydome Heel 20 Waffle Slab Mould 90×90×30 cm

This mould, with dimensions of 90×90 cm, a height of 30 cm, and a 20 cm heel in the Skydome type, is suitable for spans up to 14 meters in industrial projects, warehouses, multi-story parking lots, exhibition halls, and metro stations. For a 1000 m² ceiling, approximately 865 moulds are needed (divided by 0.81 m²). Concrete consumption is about 0.16-0.18 m³ per m² (slab thickness of 35 cm), which is 25-30% less than solid slabs. Made from recycled ABS plastic, this mould is reusable up to 100 times. The 20 cm heel provides better shear resistance, reducing the need for high-slump concrete and optimizing concreting costs. The Skydome’s domed design offers superior sound insulation and an attractive grid-like appearance for exposed finishes. The lightweight moulds (3-5 kg) allow easy installation without cranes. Buyers should ensure mould resistance to concrete pressure, polished surface for easy demoulding, and locking connections for secure assembly. The price of two-way waffle slab moulds in 2025 is approximately $15-$35 per mould. Used waffle slab moulds should be free of cracks. Scaffolding with modular scaffolding and prop jacks is essential for 14-meter spans. The maximum span of 14 meters ensures safety, deflection, and vibration control. Precise mould arrangement per engineering plans reduces material use. Purchasing from Alborz Ghaleb guarantees quality and after-sales service. Standard mould release oil or simple water cleaning ensures easy demoulding and durability up to 100 cycles. Consulting engineers for project-specific load compatibility and optimized execution is recommended.Skydome Heel 20 Waffle Slab Mould 90×90×40 cm

This mould, with dimensions of 90×90 cm and a height of 40 cm in the Skydome Duo type, is suitable for spans up to 15 meters in industrial projects, warehouses, and bridges. For a 1000 m² ceiling, approximately 865 moulds are needed (divided by 0.81 m²). Concrete consumption is about 0.20-0.22 m³ per m² (slab thickness of 45 cm). The Skydome Duo likely features improved strength or easier installation. Buyers should focus on polypropylene quality, polished surface, and locking connections. The price of two-way waffle slab moulds in 2025 is approximately $17-$39 per mould. Used waffle slab moulds should be free of cracks. Scaffolding with modular scaffolding and prop jacks is essential for 15-meter spans. The maximum span of 15 meters ensures safety and deflection control. Precise mould arrangement reduces material use. Purchasing from Alborz Ghaleb guarantees quality. Mould oil maintenance extends durability up to 50 cycles. Consulting engineers for optimal use of this mould type is recommended.Waffle Slab Mould 95×95×40 cm

This mould, with dimensions of 95×95 cm and a height of 40 cm, is suitable for spans up to 16 meters in large industrial projects, bridges, and extensive warehouses. For a 1000 m² ceiling, approximately 775 moulds are needed (divided by 0.9025 m²). Concrete consumption is about 0.20-0.22 m³ per m² (slab thickness of 45 cm), which is 20% less than solid slabs. Buyers should ensure mould resistance to concrete pressure, lightweight design for easy handling, and locking connections for secure assembly. The price of two-way waffle slab moulds is approximately $14-$26 per mould. Used waffle slab moulds should be inspected for cracks and wear. Scaffolding with modular scaffolding and prop jacks is essential for 16-meter spans. The maximum span of 16 meters is suitable for specific projects with precise engineering design. Precise mould arrangement optimizes material use. Purchasing from Alborz Ghaleb ensures quality and after-sales service. Standard mould release oil ensures easy demoulding and extended durability up to 50 cycles.