Is Your Formwork Stealing Your Profit? It’s Time for a Change.

Let’s be honest. How many hours has your crew wasted waiting for the crane? How much money have you lost on rusted steel panels, warped plywood, and the endless cycle of cleaning and oiling? For years, the construction industry has accepted these inefficiencies as “the cost of doing business.”

We believe that’s unacceptable.

Welcome to the new standard in concrete construction. This isn’t just a guide to plastic formwork; it’s a blueprint for reclaiming your time, your budget, and your competitive edge. We’re here to show you how a simple switch in material can lead to a revolutionary shift in your project’s profitability and speed.

The Moment of Truth: Plastic vs. Steel vs. Plywood in a Real-World Showdown

Forget marketing jargon. Let’s talk numbers and facts that impact your job site every single day. We built a comparison based on data from hundreds of projects.

| Factor | Alborz Ghaleb Modern Plastic Formwork | Traditional Steel Formwork | Disposable Plywood Formwork |

|---|---|---|---|

| Handling & Labor | One-person job. A 12 kg/m² panel means no crane, smaller crews, and a safer site. | Crane-dependent. A 60 kg/m² panel is a safety risk and a logistical nightmare. | Heavy and awkward. Degrades with each use. |

| Project Speed | Up to 2x faster cycle times. Rapid, tool-free assembly. Immediate stripping and reuse. | Slow. Crane bottlenecks, bolting, and heavy maneuvering slow everything down. | Very slow. Requires extensive on-site cutting, bracing, and assembly. |

| Cost Per Use | Extremely Low. Guaranteed for 100+ reuses, your cost approaches zero over time. | High. High initial cost and significant repair/maintenance expenses. | Deceptively high. Appears cheap initially, but with <10 reuses, the total cost is huge. |

| Concrete Finish Quality | Architectural Grade (F5). Glass-smooth finish. No plastering required. | Good, but prone to rust stains and seam marks, requiring costly remedial work. | Poor to fair. Wood grain transfer and water damage necessitate extensive finishing. |

| Total Cost of Ownership | Lowest. Minimal labor, no crane, no oil, zero scrap value (no theft), massive reusability. | Highest. Includes crane rental, large crews, repair, oil, and high risk of theft. | Hidden High Costs. Constant replacement, high waste disposal fees, and intensive labor. |

The verdict is clear: Continuing with steel or plywood isn’t just a preference; it’s a conscious decision to spend more money for a slower, less efficient process.

What Exactly is Plastic Concrete Formwork? A Pivotal Role in Modern Construction

Plastic concrete formwork—also known as “polymer formwork” or “concrete plastic formwork”—is an innovative, lightweight mold crafted from high-performance polymers like ABS (Acrylonitrile Butadiene Styrene), PP (Polypropylene), or PE (Polyethylene). It is used to shape fresh concrete in construction projects until it sets into structures such as walls, columns, slabs, foundations, or specialty forms.

Manufactured in Iran by Alborz Formwork, our plastic formwork systems feature modular designs with rapid pin or lever connections. These systems offer a cost-effective and durable alternative to metal or timber formwork, revolutionizing efficiency and sustainability in the construction industry.

Plastic concrete formwork plays a pivotal role in modern construction by enhancing speed, reducing costs, and improving quality. In a residential tower project in Tehran, our ABS forms, proudly made in Iran, delivered smooth, exposed concrete walls without the need for oiling, reducing labor time by 25%. In a humid villa project in Mazandaran, its rust-free nature outperformed metal forms, saving maintenance costs in salty, wet conditions. With global metal prices experiencing volatility (e.g., a 20% increase in 2024), the affordability and practicality of plastic formwork, manufactured in Iran, make it a rising star.

Want to know the plastic formwork price or make a purchase from Iran? Contact us at +98 912 139 0683 or visit our Metal Formwork page for comparisons!

From Job Site Frustration to Unprecedented Efficiency: 4 Ways Plastic Formwork Transforms Your Workflow

This is where the theory meets reality. Here’s how our system solves your biggest and most costly headaches.

1. The Problem of the Overburdened Crane: Reclaim Your Timeline

Every site manager knows the pain: your entire schedule is held hostage by crane availability. Our solution is simple: make the crane irrelevant for your formwork. Our panels are so light that a two-person crew can erect 50 square meters of wall formwork in just a few hours, by hand. This immediately decouples your formwork cycle from your crane schedule, allowing you to pour concrete faster and move to the next section without delay. This isn’t an incremental improvement; it’s a fundamental change to your critical path.

2. The Problem of Spiraling Labor Costs: Do More with Less

Skilled labor is expensive and hard to find. Why waste it on hauling heavy, cumbersome materials? The intuitive, lightweight nature of our system means:

- Smaller Crews: You can achieve the same (or better) results with a smaller, more focused team.

- Reduced Fatigue & Higher Safety: Lighter loads mean fewer injuries, less worker fatigue, and higher morale and productivity throughout the day.

- Quantifiable Savings: Our clients regularly report labor cost reductions between 30% and 50% on their formwork activities alone.

3. The Problem of the Imperfect Finish: Eliminate an Entire Step in Your Process

Every dollar spent on plastering, grinding, or patching concrete is a dollar that shouldn’t have been spent. The engineered, non-porous surface of our plastic formwork creates a perfectly smooth, architectural-grade concrete finish. Imagine a basement, parking garage, or structural wall that needs no further aesthetic treatment. That’s not a dream; it’s a standard result with our system.

4. The Problem of Asset Depreciation: An Investment That Pays You Back

Steel rusts. Plywood delaminates. Both end up in a scrap heap. Our plastic formwork is an asset. Made from a high-density polymer composite, it is impervious to water, UV rays, and construction chemicals. With an ROI that often breaks even after just 15 uses and a lifespan of over 100, it’s not an expense—it’s one of the smartest assets you can own.

Versatility in Action: One System, Infinite Applications

The modular design of the Alborz Ghaleb system, manufactured in Iran, provides unparalleled flexibility for a wide range of concrete structures.

- Wall Formwork: Shapes everything from boundary to shear walls. Our flat panels and precision corners (internal/external) ensure perfect alignment. A Tehran project used our forms, made in Iran, for 20 cm shear walls with flawless results, saving 20% on finishing. The lightweight nature makes them easy to handle, and their durability ensures they can be reused many times, making them a cost-effective choice.

- Slab Formwork: Replaces traditional plywood in flat or joist slab construction. Its moisture-resistant and lightweight properties make it a superior choice, as showcased in a 400 m² factory pour in Shiraz, all using products from our Iranian facilities.

- Column Formwork: Our prismatic design is adjustable from 20×20 to 60×60 cm, making it highly versatile for square, rectangular, or even L-shaped columns. An Isfahan villa used our Iranian-made forms for decorative pillars with zero defects. These panels are connected using a simple nylon handle with a 90-degree twist, and tie rods prevent bulging on larger columns.

- Foundation Formwork: Ideal for strip or raft foundations. Its portability and economy were proven in a Yazd warehouse project, which cut transport costs significantly using our forms, manufactured in Iran.

- Special Structures: We engineer custom forms for pools, manholes, stairs, or bridges. A pool project in Mazandaran achieved perfect curved finishes, all crafted locally in our Iranian facilities.

The Art of Engineering: The Manufacturing Process in Iran

Producing our plastic concrete formwork is a precision-driven process leveraging advanced polymer technology, all performed at Alborz Formwork’s state-of-the-art facilities in Iran:

- Design Phase: Our Iranian engineers design panels (e.g., 60×120 cm) for specific uses—walls, columns, slabs—with integrated lever or pin slots for fast assembly. Forms are engineered to meet pressures up to 80 kN/m² (for ABS).

- Material Selection: We select high-grade polymers—ABS for high strength, PP for a balance of features, or recycled polymers for cost-effectiveness. All materials are sourced and processed in Iran under strict quality control.

- Injection Molding: Polymers are melted (e.g., at 220°C for ABS) and injected into custom steel molds using advanced Iranian machinery. This single-step process produces uniform, precise panels far faster than metal’s multi-stage fabrication.

- Quality Testing: Forms undergo rigorous pressure tests, flexibility checks, and surface inspections in our Iranian labs to guarantee flawless field performance.

- Packaging and Delivery: Lightweight forms (e.g., an 11 kg ABS panel) are packaged and shipped directly from our factories in Tehran, Karaj, Isfahan, and Yazd.

Engineered in Iran: A Deep Dive into Our Product Lines

Manufactured in Iran by Alborz Formwork, our polymer formwork systems are tailored to modern construction needs.

1. Plastic Modular “Ledge 5” Formwork (Pin-Type)

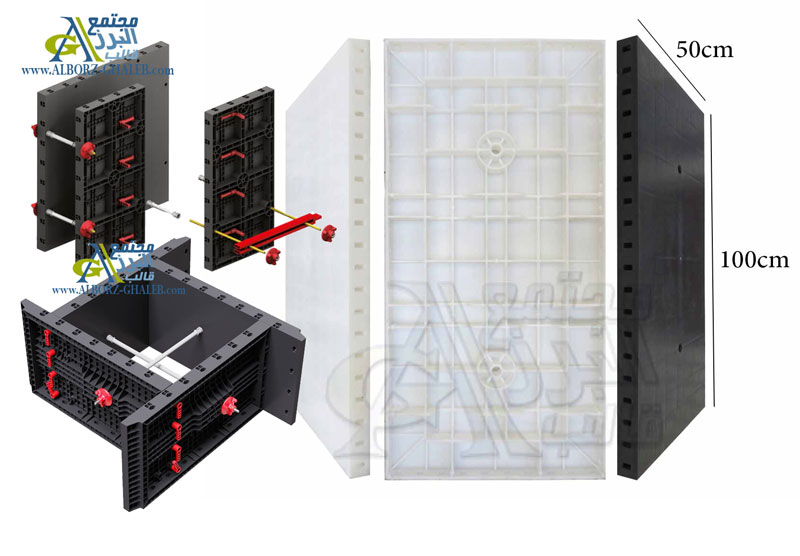

- Specifications: Ultra-light sizes like 50×100 cm (5.2 kg), available in white (new) or black (recycled) material. Connects to metal forms with pins/wedges or levers.

- Advantages: Ultra-light, versatile for hybrid setups, and highly affordable. Reusable up to 60 times.

- Applications: Shear walls, slabs, foundations. A Tehran apartment cut wall setup time by 25% with these forms, made in Iran.

2. Plastic Modular “Ledge 8” Formwork (Lever-Type ABS/PP)

- Specifications: High-strength panels like 60×120 cm (11 kg for ABS, 9.1 kg for PP) with rapid red PA66 levers. ABS withstands up to 80 kN/m².

- Advantages: Silent, hammer-free assembly, exceptional durability, and a smooth finish for exposed concrete. Reusable up to 100 times with ABS.

- Applications: High walls, columns, large slabs. A Shiraz tower used our ABS lever forms, made in Iran, for flawless 6-meter walls.

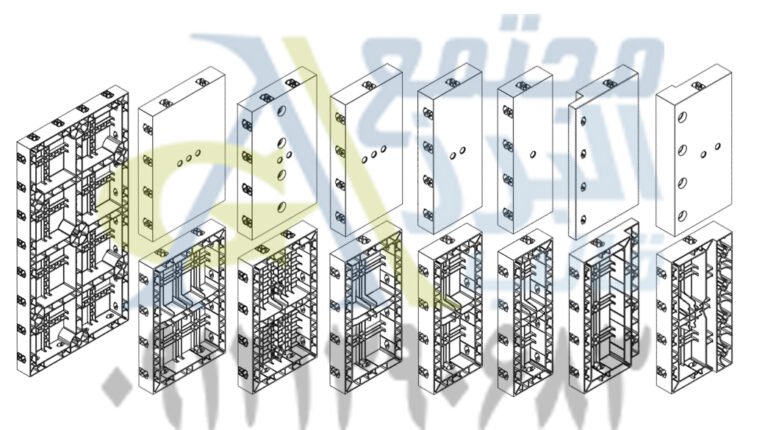

3. Plastic Prismatic Column Formwork

- Specifications: Adjustable from 20×20 cm to 60×60 cm, with an entire set weighing ~80 kg. Multiple bolt holes ensure stability.

- Advantages: Highly flexible for square, rectangular, or L-shaped columns, lightweight, and easy to strip.

- Applications: Structural or decorative columns. An Isfahan villa showcased intricate pillars with zero defects using these forms, manufactured in Iran.

The Honest Assessment: A Transparent Look at Benefits and Drawbacks

We believe in empowering our clients with complete information.

The Drawbacks (and How We Mitigate Them)

- Lower Load Capacity vs. Steel: While our ABS system is rated for a robust 80 kN/m², it may not be suitable for massive civil projects like dams where steel’s higher limits are necessary. Our engineers will always specify the correct system for your project’s needs.

- Heat Sensitivity: The material can soften in temperatures exceeding 80°C. This simply requires smart site management, such as avoiding midday pouring in extreme summer heat.

- Non-Repairable Panels: Unlike steel that can be welded, a broken panel cannot be repaired. However, we stand by our product’s durability and offer a 50% replacement cost program, a commitment to our partners.

The Overwhelming Benefits

- Lightweight Design: 10-16 kg/m² vs. steel’s 40+ kg/m², easy one-person handling, no cranes needed.

- Non-Stick Superior Finish: Minimal concrete adhesion means fast stripping without oil, saving up to 20% on labor.

- 100% Rust-Free: Ideal for humid climates like North Iran, unlike metal which needs constant maintenance.

- Affordable: The competitive plastic formwork price makes it a smart choice for projects of all sizes.

- Quick Setup: Lever or pin systems have proven to cut assembly time by 30% or more.

- Eco-Friendly: Recyclable material, with a 50% trade-in for broken forms to reduce waste.

Maximizing Your Investment: Maintenance Tips for Polymer Formwork

To extend the life of your polymer formwork, manufactured in Iran, and achieve over 100 reuses:

- Clean Simply: Use only water and a mild soap after use. Avoid harsh chemicals.

- Avoid High Heat: Store below 80°C in shaded areas to prevent any risk of warping.

- Dry Storage: Keep panels in a dry, shaded area to maintain their precise shape.

- Handle Gently: Avoid dropping panels from heights to prevent cracks. Remember our 50% replacement commitment.

Seeing is Believing: Real-World Case Studies

1: The High-Rise Challenge

- Project: A 25-story residential tower in Mashhad.

- The Pain Point: The contractor was stuck in a 10-day cycle per floor using steel, largely due to crane bottlenecks.

- The Alborz Ghaleb Solution: We implemented our “Ledge 8” ABS formwork. The crew could strip and erect the forms for the next floor in just 2 days, entirely by hand.

- The Result: The floor cycle time was reduced to 6 days. The project was completed 50 days ahead of schedule, resulting in over $200,000 in savings on overheads.

2: The Architectural Concrete Villa

- Project: A luxury villa in a humid northern climate.

- The Pain Point: The architect had zero tolerance for imperfections or rust stains on exposed concrete walls.

- The Alborz Ghaleb Solution: We provided our rust-proof PP panels.

- The Result: A flawless, glass-like concrete finish was achieved directly from the form.

- Request a Free Consultation: Let our engineers analyze your project plans.

- Get a Custom Quote & ROI Analysis: We’ll show you the numbers for yourself.

- Transform Your Business: Join the elite contractors who have made the switch.

Ready to explore the plastic formwork price or make a purchase from Iran’s leading manufacturer? Contact our experts today.

COLUMN PLASTIC FORMWORK

for square and rectangular concrete columns – is an adjustable, lightweight, modular plastic formwork system ideal for unique form configurations.

The Star plastic column formwork system for concrete structures is a universal solution for the forming of columns, pile caps, footings, plinths, and more.

Star panels are connected using the nylon handle with a simple 90 degree twist. Tie rods and anchor nuts are used to prevent bulging on larger width columns.

Form columns from 200 – 1000 mm wide in 105 different size combinations

Because the Star column formwork system is made from high-strength, lightweight ABS at less than 10 kg per piece, crane time can be drastically reduced.

Smart formworkers are experiencing a significant saving of time and resource costs to their jobs.

.ABS

| 1 | Ap 120 | flat panel | 60 120 | 11 KG |

| 2 | Ap 20 | flat panel | 60 20 | 2.1 KG |

| 3 | Ap 25 | flat panel | 60 25 | 2.5 KG |

| 4 | Ap 30 | flat panel | 60 30 | 3.1 KG |

| 5 | Ap 35 | flat panel | 60 35 | 3.6 KG |

| 6 | Ap 40 | flat panel | 60 40 | 4.1 KG |

| 7 | Ap IN | in | 60 in | 2.1 KG |

| 8 | Ap OUT | out | 60 out | 2.8 KG |

| 9 | HDL | — | — | — |

PP

| 1 | Pp 120 | flat panel | 60* 120 | 9.1 KG |

| 2 | Pp 20 | flat panel | 60* 20 | 1.8 KG |

| 3 | Pp 25 | flat panel | 60* 25 | 2.2 KG |

| 4 | Pp 30 | flat panel | 60* 30 | 2.5 KG |

| 5 | Pp 35 | flat panel | 60* 35 | 3.0 KG |

| 6 | Pp 40 | flat panel | 60* 40 | 4.1 KG |

| 7 | Pp IN | in | 60* in | 2.0 KG |

| 8 | Pp OUT | out | 60* out | 2.6 KG |

| 9 | HDL | — | — | — |

Advantages Plastic formwork products

Advantages and Disadvantages Plastic formwork products

Easy to demould. The concrete does not stick to the board surface, no release agent is required, and it is easy to demould and clean the dust.

It is light in weight and has strong process adaptability. It can be sawed, planed, drilled, nailed, and can be formed into any geometric shape at will to meet the needs of building formwork of various shapes.

The formwork is spliced tightly and flatly, and the surface degree and smoothness of the concrete structure after demoulding exceed the technical requirements of the existing clear water formwork, and there is no need for secondary plastering, saving labor and materials.

Disadvantages Plastic formwork products

The static bending strength and static bending elastic modulus of plastic building formwork are smaller than other formwork.

At present, the plastic building formwork is mainly used as the roof and floor formwork in the form of flat plate, and the bearing capacity is low. As long as the spacing of the secondary beams is properly controlled, the construction requirements can be met. But to be used as wall column formwork, it must be processed into steel frame plastic formwork.

The coefficient of thermal expansion and contraction of plastic sheets is larger than that of aluminum formwork, so plastic building formwork is greatly affected by temperature. For example, in the high temperature period in summer, the temperature difference between day and night can reach 40 °C. Up to 3mm ~ 4mm. To solve the problem of expansion, you can choose an average temperature time to lay the slabs during construction, or add sponge strips between the slabs, which can eliminate the gaps in the formwork, ensure that the pouring concrete does not leak, and can solve the problem of high temperature. Arching problem.

whatsapp: https://wa.me/c/989121390683

web : www.alborz-ghaleb.com

telegram : http://t.me/alborz_ghaleb