Why Tunnel Formwork is a Smart Choice for Modern Construction

Tunnel formwork, also known as tunnel form system, is one of the most advanced concrete formwork solutions in the construction industry. By enabling simultaneous casting of walls and slabs, it delivers unparalleled speed, quality, and cost efficiency to your projects. Ideal for mass housing, hospitals, hotels, and large infrastructure like bridges and metro stations, tunnel formwork reduces construction time by up to 50% and finishing work by up to 60%. This system not only cuts costs but also provides exceptional resistance to earthquakes and fire.

In this comprehensive guide from Alborz Ghaleb, we explore everything about tunnel formwork, from its definition and benefits to execution processes, applications, and buying tips. If you’re looking to accelerate your construction projects, this article is for you. For more on other formwork systems, visit our concrete modular metal formwork page.

Ready to transform your project? Contact Alborz Ghaleb Today for expert solutions!

What is Tunnel Formwork?

Definition and Concept

Tunnel formwork is a metal or composite-based formwork system designed for seamless concrete casting of walls and slabs in large-scale construction projects. By creating cellular (tunnel-like) structures, it allows rapid, simultaneous execution of multiple structural components. Unlike traditional formwork assembled piece by piece, tunnel formwork is integrated, enabling an entire residential unit or a significant structural section to be cast in a single 24-hour cycle.

Its repetitive and structured design makes it perfect for mass housing projects with similar layouts. For projects requiring greater flexibility, consider our modular metal formwork.

History and Evolution

Developed in Europe during the 1960s to address mass housing needs, tunnel formwork has evolved to meet demands for faster, more cost-effective construction. In recent decades, its adoption in Iran has grown significantly, driven by companies like Alborz Ghaleb, which offer tunnel formwork solutions meeting international standards such as ISO 9001 and DIN. Learn more about our formwork equipment on our system scaffolding page.

Benefits and Limitations of Tunnel Formwork

Key Benefits

- Unmatched Speed: 24-hour cycles reduce construction time by up to 50%, critical for large-scale projects.

- Superior Concrete Finish: Smooth, uniform surfaces cut finishing needs by up to 60%.

- Cost Savings: Reduces rebar use by 30%, labor, and finishing materials.

- Earthquake and Fire Resistance: Seamless structures provide high resistance to seismic and fire hazards.

- High Durability: Metal tunnel forms can be reused up to 800 times with proper maintenance.

Compare with lighter systems on our concrete formwork plastic systems page.

Limitations

- High Initial Cost: ST52 steel and complex equipment increase upfront expenses.

- Specialized Labor: Requires trained workers and cranes for installation.

- Design Constraints: Less flexible for complex or non-repetitive layouts compared to modular metal formwork.

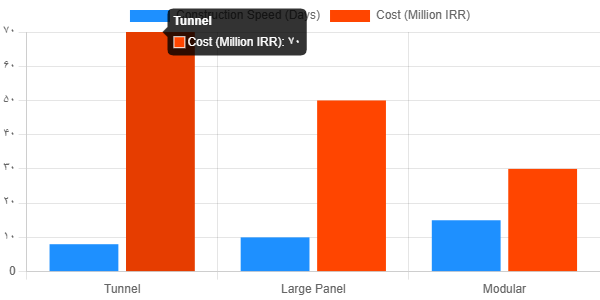

Comparison of Tunnel Formwork with Other Systems

To better understand tunnel formwork’s advantages, here’s a comparison with other common formwork systems:

| Feature | Tunnel Formwork | Large Panel Formwork | Modular Formwork |

|---|---|---|---|

| Construction Speed | Very High (24-hour cycles) | High | Moderate |

| Initial Cost | High | High | Low |

| Concrete Surface Quality | Excellent (No Finishing) | Excellent | Moderate |

| Design Flexibility | Low (Repetitive Plans) | Moderate | High |

| Formwork Weight | 2–8 tons | 1.5–7.5 tons | 55 kg |

| Applications | Mass Housing | Large Projects | Small to Medium Projects |

Tunnel formwork excels in mass housing with repetitive plans, while modular formwork is more cost-effective for smaller projects.

Components of Tunnel Formwork

Tunnel formwork consists of several critical components, each playing a vital role:

- Main Panels: ST52 steel sheets (3–5 mm thick, 2–8 tons) for walls and slabs.

- Brackets: Connect panels and withstand concrete pressure.

- Shooting Pipes: Guide concrete into the formwork.

- Adjustment Jacks: Ensure vertical and horizontal alignment with 0.1° precision.

- Mid-Bolts: Prevent panels from opening during casting.

- Modular Scaffolding: Facilitates panel movement at higher levels.

- Accessories: Clamps, pins, and lifting hooks for stability and transport.

- Connecting Bolts: Secure panels against concrete pressure.

- Leveling Jacks: Adjust formwork verticality.

- Shoes and Pins: Enhance system stability.

- Lifting Hooks: Enable crane transport of panels up to 10 tons.

For efficient panel movement, explore our system scaffolding solutions.

Tunnel Formwork Design and Execution Process

Design

Design is conducted using software like AutoCAD or Tekla, calculating hydrostatic concrete pressure (25–30 kN/m²) and structural dimensions. Pre-fabricated openings for doors, windows, and utilities are included.

Production

Metal panels are manufactured using CO2 welding with ST52 steel, adhering to ISO 9001 and ACI 347 standards. Polymer panels are injection-molded for specific projects.

Execution Steps

- Planning: Develop architectural plans and specify openings.

- Site Preparation: Level the foundation with 5 mm precision and install adjustment jacks.

- Panel Installation: Transport panels via cranes (10-ton capacity) and secure with brackets and bolts.

- Rebar Placement: Install standard rebars (e.g., AIII) per design.

- Concrete Casting: Pour C30 or C40 concrete using vibrators for uniform compaction.

- Formwork Removal: Dismantle panels after 24–48 hours of initial setting.

- Relocation: Move panels to higher levels using lifting hooks.

- Quality Control: Verify wall alignment and surface quality, correcting defects.

Ensure safety during installation with our system scaffolding.

Applications of Tunnel Formwork

Due to its speed and quality, tunnel formwork is used in diverse projects:

- Mass Housing: Residential towers in cities like Tehran and Mashhad.

- Commercial Projects: Hotels, shopping centers, and office buildings.

- Industrial Infrastructure: Bridges, dams, and metro stations.

- Hospitals and Schools: Structures requiring high seismic resistance.

For smaller projects, consider our modular metal formwork.

How Tunnel Formwork Reduces Project Costs

Tunnel formwork significantly lowers costs through:

- 50% Time Reduction: 24-hour cycles enable earlier project completion.

- 60% Finishing Savings: Smooth surfaces eliminate plastering needs.

- 30% Rebar Reduction: Optimized cellular structure design.

- Formwork Durability: Reusable up to 800 cycles, reducing long-term costs.

For budget-friendly alternatives, visit our plastic formwork systems.

Key Tips for Buying Tunnel Formwork

To select high-quality tunnel formwork, consider:

- Material Quality: ST52 steel sheets (3–5 mm) meeting DIN or ASTM standards.

- Accessories: Galvanized brackets, bolts, and jacks for durability.

- Customization: Flexible panels for specific project layouts.

- Technical Support: Choose providers like Alborz Ghaleb for consultation and training.

- Price and Warranty: Compare costs with quality and after-sales services.

Learn more about formwork equipment on our system scaffolding page.

Why Choose Alborz Ghaleb?

With over 20 years of experience, Alborz Ghaleb is a leading tunnel formwork provider in Iran, offering:

- Superior Quality: Products meet international standards.

- Custom Designs: Tailored panels for unique project needs.

- Expert Support: Professional consultation and training.

- Competitive Pricing: High-quality solutions at affordable rates.

Projects like the Karkheh Dam and Mehr Housing testify to our commitment. Explore our modular metal formwork for more options.

Frequently Asked Questions (FAQs) About Tunnel Formwork

What is tunnel formwork, and how does it differ from large panel formwork?

Tunnel formwork enables simultaneous wall and slab casting for repetitive plans, while large panel formwork offers more flexibility for varied layouts.

Is tunnel formwork suitable for small projects?

For smaller projects, systems/ are more cost-effective due to lower costs and lighter weight.

What is the approximate cost of tunnel formwork?

Costs depend on panel size, quality, and quantity. Contact Alborz for a Precise Quote.

How to evaluate tunnel formwork quality?

Check sheet thickness, production standards (e.g., ISO 9001), and after-sales support.

Is tunnel formwork reusable?

Yes, metal panels can be reused up to 800 times with proper maintenance, saving costs.

Conclusion

Tunnel formwork is a cutting-edge solution for large-scale construction, offering unmatched speed, quality, and cost efficiency. Its seamless casting, reduced finishing needs, and durability make it a top choice for modern contractors and engineers. Partner with Alborz Ghaleb to ensure your project’s success.

Discover more about modular metal formwork, plastic formwork, or system scaffolding on our website. Ready to start? Contact Alborz Ghaleb Now!