Why Is Prop Jack Removal Timing Critical?

In construction projects, prop jacks are essential for supporting joist and block roofs or other concrete structures during the curing process. Removing prop jacks too early risks structural collapse, while delayed removal can cause project delays and increased costs. The prop jack removal timing depends on factors like concrete type, ambient temperature, and engineering standards. Proper timing ensures structural safety, optimizes costs, and accelerates project completion.

Alborz Formwork, with over 10 years of experience in manufacturing high-quality construction equipment, offers reliable solutions like prop jacks for construction and advanced scaffolding systems. This comprehensive guide covers everything you need to know about prop jack removal: influencing factors, standards, practical steps, safety tips, and a real-world case study. Ready to optimize your construction projects? Contact Alborz Formwork at +98 912 139 0683 for expert advice.

What Are Prop Jacks?

Prop jacks, also known as construction props, are temporary support structures used to hold concrete roofs, particularly joist and block systems, during the pouring and initial curing stages. Typically made from galvanized steel or aluminum, these props come in various types, including cross props, Iraqi props, and plumb support props, each designed for specific project needs.

- Cross Props: Ideal for large-scale projects with adjustable height capabilities. Explore our prop jacks for construction.

- Iraqi Props: Lightweight and cost-effective, perfect for smaller projects.

- Plumb Support Props: Designed for high-strength support in complex structures. Learn more about our system scaffolding.

Choosing the right prop depends on factors like roof height, structural load, and budget. Alborz Formwork provides a range of high-quality prop jacks to meet diverse project requirements.

Factors Affecting Prop Jack Removal Timing

The appropriate time to remove prop jacks depends on several critical factors that must be carefully evaluated:

- Concrete Type: Higher-strength concretes (e.g., C30 or C35) achieve required strength faster.

- Ambient Temperature: A range of 15-25°C is ideal; lower temperatures slow curing.

- Humidity: Higher humidity aids better concrete curing.

- Structural Load: Heavier roofs require longer support times.

- Engineering Standards: Iranian standards (e.g., Iran Concrete Code) recommend 7-21 days, depending on conditions.

For safety, verify concrete strength using tests like the Schmidt hammer or cube sampling. For robust support solutions, check out our prop jacks for construction.

Steps for Removing Prop Jacks

Removing prop jacks is a delicate process requiring precision to ensure structural integrity. Follow these steps:

- Verify Concrete Strength: Use tests or consult with a structural engineer to confirm the concrete has reached at least 70% of its design strength (typically 21 MPa).

- Prepare Tools: Gather appropriate tools, such as wrenches or hydraulic equipment, and ensure safety gear is in place.

- Gradual Removal: Lower props incrementally (10-15 cm per step) from the center outward to evenly distribute load release.

- Inspect for Cracks: Check the roof for cracks or deformation before and after removal.

- Clean and Store: Clean props and store them in a dry environment for future use.

Safety Tips: – Avoid premature removal to prevent structural failure. – Use safety gear like helmets and gloves. – Coordinate with a supervising engineer. For durable and reliable props, explore our system scaffolding.

Prop Jack Removal Schedule

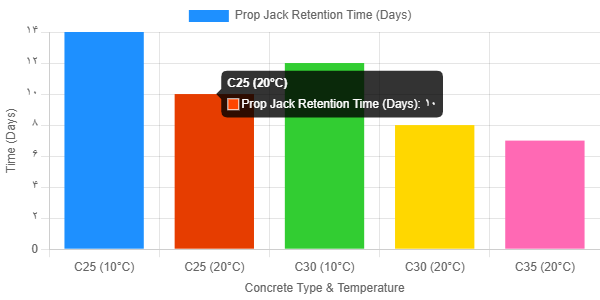

The table below provides a recommended schedule for prop jack removal based on concrete type and ambient temperature:

| Concrete Type | Temperature (°C) | Retention Time (Days) |

|---|---|---|

| C25 | 10-15 | 10-14 |

| C25 | 15-25 | 7-10 |

| C30 | 10-15 | 8-12 |

| C30 | 15-25 | 6-8 |

| C35 | 15-25 | 5-7 |

Note: This schedule aligns with the Iran Concrete Code (ABA). Consult a structural engineer for project-specific requirements. For high-quality props suited for large projects, visit our prop jacks for construction.

Safety Tips and Common Mistakes

Safety Tips

- Verify Concrete Strength: Use standardized tests to confirm strength before removal.

- Use Safety Gear: Workers should wear helmets, gloves, and safety boots.

- Gradual Removal: Sudden removal can damage the structure.

- Engineering Supervision: A structural engineer should oversee the process.

Common Mistakes

- Premature Removal: Removing props before sufficient curing leads to cracks.

- Inadequate Vibration: Air bubbles weaken concrete strength.

- Misaligned Props: Poor alignment causes uneven roofs.

Ensure safety and efficiency with our reliable system scaffolding.

Maintaining and Repairing Prop Jacks

Regular maintenance extends the lifespan of prop jacks:

- Cleaning: Wash props with water and a brush after each use.

- Stain Removal: Use mild detergents to remove concrete residue.

- Storage: Store props in a dry, moisture-free environment.

- Repairs: Weld cracks in metal props or use resin for plastic ones.

Explore our durable prop jacks for construction for long-lasting performance.

Case Study: Successful Prop Jack Implementation

Alborz Formwork has successfully implemented prop jacks in numerous projects:

- Tehran Residential Towers: Used prop jacks for construction to support 3.5-meter-high joist and block roofs, ensuring safety and timely completion.

- Karkheh Infrastructure Project: Employed system scaffolding for heavy-duty structural support.

These projects highlight the reliability of Alborz Formwork’s solutions. Contact us at +98 912 139 0683 for similar success in your projects.

1. What is the best time to remove prop jacks?

Typically, 7-14 days, depending on concrete type and temperature. Refer to the schedule table above for details.

2. Is early removal of prop jacks dangerous?

Yes, premature removal can cause roof collapse or cracking. Always verify concrete strength first.

3. What concrete is best for joist and block roofs?

C30 or C35 concrete with a water-cement ratio of 0.35-0.4 ensures fast curing and high strength.

4. How can I safely remove prop jacks?

Use proper tools, remove props gradually, and coordinate with an engineer. Check our prop jacks for construction for reliable options.

5. Where can I get expert advice or purchase prop jacks?

Contact Alborz Formwork at +98 912 139 0683 or explore our system scaffolding solutions.

Why Choose Alborz Formwork?

Alborz Formwork is a trusted partner for contractors and engineers, offering:

- Superior Quality: ST37 galvanized steel props for maximum durability.

- Wide Range: From prop jacks for construction to system scaffolding.

- Expert Support: Free technical consultation for your projects.

- Competitive Pricing: High-quality solutions at affordable rates.

Elevate your project with Alborz Formwork. Call us at +98 912 139 0683 today!

Conclusion: Optimize Your Projects with Alborz Formwork

Proper prop jack removal timing is key to ensuring safety and efficiency in construction projects. By following engineering standards, using high-quality props, and consulting experts, you can complete your projects faster and safer. Alborz Formwork offers a range of solutions, including prop jacks for construction and system scaffolding, to support your success.